Smart manufacturing represents the forefront of modern industrial innovation. Integrating advanced technologies like artificial intelligence, the Internet of Things (IoT), and automation, smart manufacturing systems are designed to optimize production processes, improve efficiency, and reduce costs.

As we move into 2024, several emerging trends are set to revolutionize the way we think about and implement smart manufacturing. In this article, we will explore 10 game-changing trends in smart manufacturing that you need to know.

Introduction

Smart manufacturing is transforming the traditional manufacturing landscape by leveraging advanced technologies to create more efficient, flexible, and responsive production systems.

Staying updated with the latest trends is crucial for businesses to maintain a competitive edge and adapt to the ever-evolving market demands. This article highlights 10 significant trends that are shaping the future of smart manufacturing in 2024.

1. Integration of Artificial Intelligence

Artificial intelligence (AI) is at the core of the smart manufacturing revolution. AI enables machines to learn from data, identify patterns, and make decisions with minimal human intervention. In 2024, the integration of AI in smart manufacturing is expected to grow, driving improvements in various areas such as predictive maintenance, quality control, and process optimization.

Benefits of AI in Smart Manufacturing:

- Predictive maintenance reduces downtime by forecasting equipment failures before they occur.

- AI-driven quality control ensures consistent product standards by detecting defects in real-time.

- Process optimization through AI algorithms enhances efficiency and reduces waste.

Examples:

- AI-powered robots that can adapt to different tasks on the production line.

- Machine learning algorithms that predict machinery failures and schedule maintenance accordingly.

2. Adoption of 5G Technology

The adoption of 5G technology is set to revolutionize smart manufacturing by providing ultra-fast, reliable, and low-latency connectivity. 5G enables real-time data processing and seamless communication between devices, which is essential for the efficiency of smart factories.

Impact of 5G on Smart Manufacturing:

- Enhanced connectivity allows for real-time monitoring and control of manufacturing processes.

- Improved data transfer speeds facilitate the integration of more complex IoT systems.

- Lower latency ensures quicker response times for automated systems.

Case Studies:

- Manufacturing plants that have implemented 5G to connect their robotic systems, resulting in increased productivity and reduced operational costs.

3. Expansion of IoT in Manufacturing

The Internet of Things (IoT) is a fundamental component of smart manufacturing, enabling the connection and communication of various devices and systems. In 2024, the expansion of IoT in manufacturing is expected to enhance data collection, monitoring, and control capabilities.

Benefits of IoT in Smart Manufacturing:

- Continuous monitoring of machinery and equipment to ensure optimal performance.

- Real-time data collection helps in making informed decisions and improving processes.

- Enhanced supply chain management through improved tracking and inventory management.

Examples:

- IoT sensors that monitor temperature, humidity, and vibration levels in real-time.

- Smart warehouses that use IoT to track inventory levels and optimize storage.

4. Advancements in Robotics and Automation

Robotics and automation have always been integral to manufacturing, but advancements in these technologies are taking smart manufacturing to new heights. In 2024, we expect to see more sophisticated and versatile robotic systems that can perform a wider range of tasks with greater precision.

Benefits of Advanced Robotics:

- Increased efficiency and productivity due to faster and more accurate operations.

- Reduced human error and enhanced safety in the workplace.

- Ability to handle complex and repetitive tasks, freeing up human workers for higher-level duties.

Examples:

- Collaborative robots (cobots) that work alongside human operators to enhance productivity.

- Automated guided vehicles (AGVs) that transport materials within the factory floor.

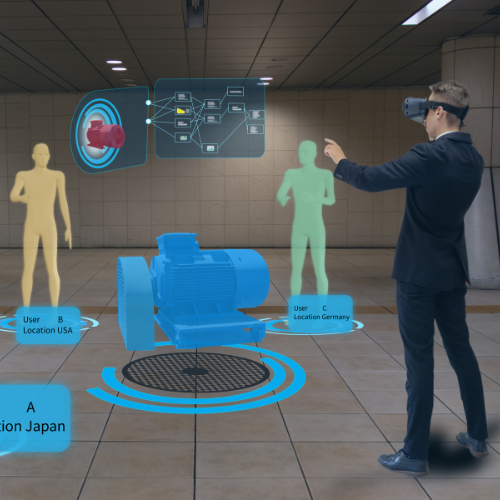

5. Implementation of Digital Twins

Digital twins are virtual replicas of physical assets, systems, or processes that are used to simulate, analyze, and optimize real-world counterparts. The implementation of digital twins in smart manufacturing is gaining traction as it offers numerous benefits for efficiency and innovation.

Benefits of Digital Twins:

- Enables real-time monitoring and simulation of production processes.

- Identifies potential issues before they occur, reducing downtime and maintenance costs.

- Facilitates innovation by allowing for virtual testing and prototyping of new designs.

Real-World Examples:

- Aerospace manufacturers using digital twins to simulate and optimize aircraft assembly processes.

- Automotive companies creating digital twins of their production lines to improve efficiency and quality.

6. Big Data Analytics for Enhanced Decision-Making

Big data analytics plays a crucial role in smart manufacturing by providing insights that drive informed decision-making. In 2024, the use of big data analytics is expected to become more widespread, helping manufacturers optimize processes, improve quality, and reduce costs.

Benefits of Big Data Analytics:

- Provides detailed insights into production processes, enabling continuous improvement.

- Helps identify trends and patterns that can lead to better resource allocation.

- Enhances predictive maintenance by analyzing historical data to forecast equipment failures.

Examples:

- Data analytics platforms that aggregate and analyze data from various sensors and machines.

- Predictive analytics tools that help manufacturers anticipate demand and adjust production schedules accordingly.

7. Focus on Cybersecurity

As smart manufacturing systems become more interconnected, they also become more vulnerable to cyber threats. Ensuring robust cybersecurity measures is essential to protect sensitive data and maintain operational integrity.

In 2024, the focus on cybersecurity in smart manufacturing is expected to intensify.

Challenges in Cybersecurity:

- Protecting against data breaches and unauthorized access to critical systems.

- Ensuring the integrity and confidentiality of production data.

- Mitigating the risk of cyber-attacks that could disrupt manufacturing processes.

Best Practices:

- Implementing strong encryption and access controls.

- Regularly updating and patching systems to address vulnerabilities.

- Conducting regular security audits and training employees on cybersecurity best practices.

8. Shift Towards Sustainable Manufacturing

Sustainability is becoming increasingly important in the manufacturing industry. Smart manufacturing technologies can significantly contribute to sustainability efforts by reducing waste, conserving energy, and minimizing the environmental impact of production processes.

Benefits of Sustainable Manufacturing:

- Reduces operational costs through energy savings and waste reduction.

- Enhances corporate reputation and compliance with environmental regulations.

- Promotes long-term sustainability and resource conservation.

Examples:

- Energy-efficient machinery and processes that reduce carbon footprints.

- Recycling and reuse of materials within the production cycle.

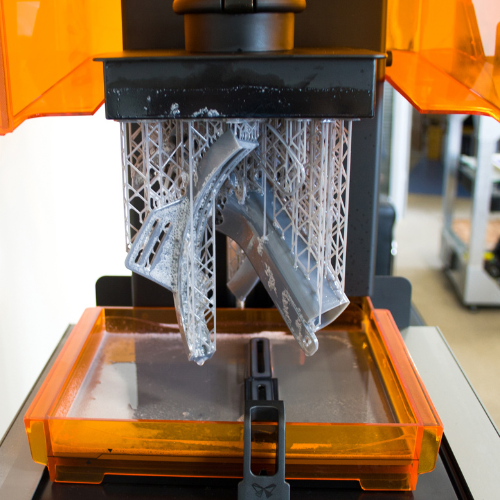

9. Adoption of Additive Manufacturing (3D Printing)

Additive manufacturing, commonly known as 3D printing, is transforming how products are designed and manufactured. In smart manufacturing, 3D printing allows for rapid prototyping, customization, and production of complex parts with minimal waste.

Benefits of Additive Manufacturing:

- Enables the creation of complex geometries that are difficult to produce with traditional methods.

- Reduces material waste and production costs.

- Speeds up the prototyping process, allowing for quicker iterations and innovation.

Examples:

- Aerospace and automotive industries using 3D printing to produce lightweight and high-performance components.

- Medical device manufacturers creating customized implants and prosthetics.

10. Enhanced Human-Machine Collaboration

The future of smart manufacturing lies in the collaboration between humans and machines. Enhanced human-machine collaboration can lead to increased productivity, improved safety, and greater job satisfaction. In 2024, we expect to see more collaborative robots (cobots) and AI-driven systems working alongside human operators.

Benefits of Human-Machine Collaboration:

- Increases efficiency by combining human creativity and decision-making with machine precision and speed.

- Improves safety by allowing machines to handle hazardous tasks.

- Enhances job satisfaction by freeing workers from repetitive and mundane tasks.

Examples:

- Cobots that assist workers in assembly lines by handling heavy lifting and precise movements.

- AI-driven systems that provide real-time insights and recommendations to human operators.

Conclusion

Smart manufacturing is continually evolving, driven by advancements in technology and the need for more efficient, flexible, and sustainable production systems. The trends highlighted in this article—ranging from artificial intelligence and 5G technology to digital twins and additive manufacturing—are set to revolutionize the manufacturing industry in 2024.

By staying informed about these trends and integrating them into their operations, manufacturers can achieve significant improvements in efficiency, productivity, and competitiveness. The future of manufacturing is smart, and embracing these game-changing trends will be crucial for success in the ever-evolving industrial landscape.